Techna offer a wide range of Linear Drive Systems which can be used as a solution in a diverse range of industries. Our range of Linear Drive Systems include Rolling Ring Linear Traverse Drives and Assemblies, Rolling Ring Linear Drive Nuts, Linear Drive Timing Belts, Guide Systems, Tension Control Dancers, a Flange Detecting System and an Automated Winding System.

Rolling Ring Drives (Linear Traverse) and Assemblies

The KI, RGK and RG Series of Rolling Ring Linear Drives and associated assemblies convert unidirectional rotary motion of a round hardened shaft into totally backlash-free, automatically reciprocating, bi-directional linear travel. Automatic reciprocating travel is achieved with a constant shaft speed and single direction of shaft rotation, with automatic reversal at set positions or controlled by pneumatic or electromagnetic actuators.

Rolling Ring Linear Drive Nuts

RS Series Rolling Ring Linear Drive Nuts convert the rotation of a plain round shaft into a linear traversing movement. Fixed pitch provides a constant speed with direction of travel according to direction of shaft rotation. This effect is achieved by using rolling rings that are mounted on roller bearings and have a specially shaped running surface. These rings are pressed against the shaft so that they roll on the surface of the shaft at a specific angle.

Linear Drive Timing Belts

Z-Series Linear Drive Timing Belts are based on rigid aluminium sections that are resistant to torsion. Several T-slots integrated in the carrier sections allow variable application and facilitate fitting. Power is transmitted from the timing belt to the load carriage via the belt joint mounted on the load carriage. Timing Belt Drives are precise, allow accurate positioning, provide high acceleration rates and speeds and have a long life.

Guide Systems

The GS Guide System allows for easy adaptation to the winding task and provides a continuously adjustable system for the accurate transfer of the traversing movement of a rolling ring drive to a guide roller that carries the material to be wound. Also available, the HGS Guide System, which is optimally suited for higher tractive forces that are caused by heavy material or more precise guidance of the material to be wound.

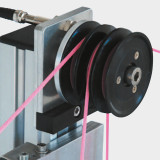

Tension Control Dancer

The Uhing Tension Control is a dancer system that helps control line tension to improve the quality of wind onto a spool. It uses pulleys on a weighted carriage to smooth out tension variations and can be configured with a feedback loop to control the speed of the payoff and/or take-up spool, thus giving ultimate fine control of the line tension.

Flange Detecting System

The Uhing Measuring System (formally known as the FA II Flange Detection System) was designed for application with pneumatically reversible rolling ring drives. The system detects the position of flanges on spools, regardless of the spool used. After a spool change, the Uhing Measuring System automatically adjusts to the new spool position and, where necessary, the new spool shape, therefore, saving significant time when spools of different type and dimensions are used.

Automated Winding System

The automated Uhing Motion Drive® winding system is based on a modified rolling ring drive which is controlled by sensors and an electronic control unit and programmed with custom software which has been engineered by Uhing to ensure that both the control unit and rolling ring drive perfectly match each other. It is simple to adapt a given winder to another material, another spool or even both at the push of a button, which reduces set up time hugely.