Techna offer a wide range of Rolling Ring Linear Drives and associated assemblies that uniquely operate by converting unidirectional rotary motion of a round hardened shaft into totally backlash-free, automatically reciprocating, bi-directional linear travel.

The KI, RGK and RG series of Uhing rolling ring linear traverse units cover shaft diameters from 15mm to 80mm, with up to 3600N side thrust. We can offer a complete range of spares and parts on request and customised solutions can be provided where required.

What are Uhing Linear Traverse Drive Units?

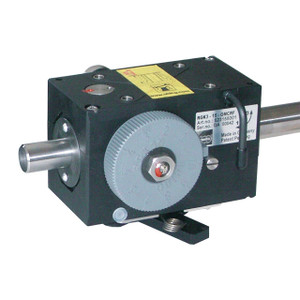

The Uhing traverse unit is a linear drive based on the rolling ring drive principle. The traverse converts the motion of a smooth, non-threaded shaft, by rotating in only one direction, into totally backlash free reciprocating linear motion. Automatic reciprocating travel is achieved with a constant shaft speed and single direction of shaft rotation, with automatic reversal at set positions, which is changeable by the user, or controlled by pneumatic or electromagnetic actuators.

Such drives are equipped with infinitely variable pitch, which is the linear travel per shaft revolution, which can be set from zero to 76mm depending on unit size. The maximum linear speed for instantaneous reversal (winding applications) is 0.25m/s and a speed of up to 4.2m/s can be achieved by utilising slowdown reversal systems.

The linear traverse units feature a simple “free-movement lever” mechanism that allows you to manually disengage and reposition the traverse unit on the shaft. All functions, such as, reversal, stroke width, pitch per revolution and free-movement, can be remotely controlled and heavy loads can be accommodated with additional load carriers.

Our rolling ring linear traverse units are suitable for many industries, such as, winding and spooling, general drive, surface treatment, measuring and testing, materials handling, converting, packaging, tyre manufacture, cutting machines and more.

Uhing Linear Traverse Servicing

Techna also provides full servicing of your Uhing rolling ring linear traverse by our engineers who have been fully trained and certified by Uhing. The traverse unit will be accurately checked for thrust, level and symmetry when servicing is completed to ensure that your unit is performing as well as the day it left the factory.

GS Guide System

The GS Guide System can be used with rolling ring linear traverse units to allow easy adaptation to the winding task and provides a continuously adjustable system for the accurate transfer of the traversing movement of the rolling ring drive to a guide roller that carries the material to be wound. Also available is the HGS Guide System, which is optimally suited for higher tractive forces that are caused by heavy material or more precise guidance of the material to be wound.

Uhing Moveable Endstops

The Uhing Moveable Endstops offer automated motion of the rolling ring drive by allowing remote adjustment of the end point reversal. This remote adjustment of the limit stops is by stepper motor to give fully automated winding which only requires the selection of the spool from the pre-programmed list. Fast and smooth winding patterns are now simple on even difficult spool shapes, such as, conical, one-sided conical, bi-conical and negatively bi-conical.