Techna offer the Uhing Measuring System (formally known as the FA II Flange Detection System), which has been specially designed for application with pneumatically reversible Rolling Ring Traverse Drives.

The system detects the position of flanges on spools, regardless of the spool used. After a spool change, the Uhing Measuring System automatically adjusts to the new spool position and, where necessary, the new spool shape, therefore, saving significant time when spools of different type and dimensions are used.

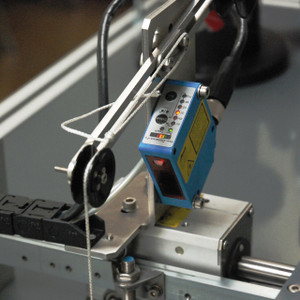

Uhing Traverse with Flange Detection Function

A sensor detecting the flange is mounted on the traversing system. At a defined point between the flanges of the spool, the distance to the spool is measured and saved as reference for each layer. While the traversing system moves, the reference distance is continuously compared to the current measured value.

A reversal is triggered as soon as the adjustable height deviation limit is exceeded. Such a height deviation occurs when the flange is detected or there is an accumulation of material on the spool. A display indicates either the current measured height or the permissible height deviation.

Advantages of Spool Flange Detection when Winding Cable or Wire

Advantages to this type of system include:

• No manual adjustment of reversal points

• Significant time savings when spools of different type and dimensions are used

• Very easy operation

• No prior experience required

• Perfect winding patterns

• No machine data required from customer

• Robust sensor technology

• Modular system