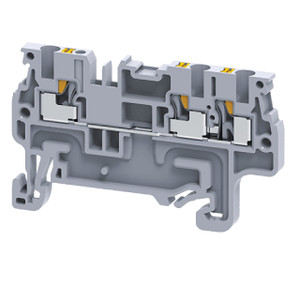

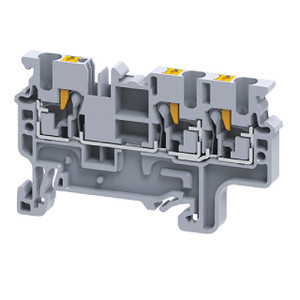

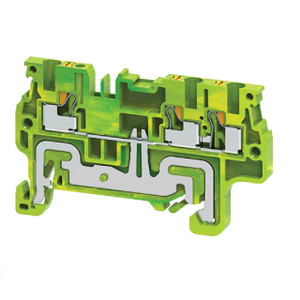

Push In Terminals are usually DIN rail mounting with (as the name suggests) push in wire connections, making them extremely efficient in terms of installation (just strip the wire and push in) and also due to the minimal use of space in a control panel or cabinet. The most compact push in terminals are extremely thin at just 3.5mm wide. Panel mount push in terminals are also manufactured for those instances where DIN rail mounting is not convenient.

Our wide range of push in terminals represent the latest advances in wire connection technology and offer significant time savings in control panel assembly by allowing toolless fast wire termination. Using non-ferrous metals to provide corrosion free and gas resistant connections, able to withstand extreme vibrations and mechanical shock, is an additional advantage. However, the absolute benefit of push in terminal blocks is a wiring time improvement of up to 400% (or put another way reducing the wiring time to one quarter) when compared to traditional screw clamp terminals.

Push in terminals are designed to allow the wire to be directly pushed into the terminal without the use of a ferrule. The specially designed spring configuration inside the terminal block provides an extremely secure connection able to withstand extreme pull out force. For example, our 2.5mm push in terminal has a very high pull out force of 95N.

Push in terminals also have their own range of accessories, most notably the pluggable shorting links which allow jumping of connections between adjacent or alternate terminals. Of course, the traditional accessories such as end plates and marking tags are all there as well.

Our wide range of push in terminals represent the latest advances in wire connection technology and offer significant time savings in control panel assembly by allowing toolless fast wire termination. Using non-ferrous metals to provide corrosion free and gas resistant connections, able to withstand extreme vibrations and mechanical shock, is an additional advantage. However, the absolute benefit of push in terminal blocks is a wiring time improvement of up to 400% (or put another way reducing the wiring time to one quarter) when compared to traditional screw clamp terminals.

Push in terminals are designed to allow the wire to be directly pushed into the terminal without the use of a ferrule. The specially designed spring configuration inside the terminal block provides an extremely secure connection able to withstand extreme pull out force. For example, our 2.5mm push in terminal has a very high pull out force of 95N.

Push in terminals also have their own range of accessories, most notably the pluggable shorting links which allow jumping of connections between adjacent or alternate terminals. Of course, the traditional accessories such as end plates and marking tags are all there as well.

-

£1.33 inc. VAT£1.11 ex. VAT

-

£1.39 inc. VAT£1.16 ex. VAT

-

£1.74 inc. VAT£1.45 ex. VAT

-

£7.24 inc. VAT£6.03 ex. VAT

-

£4.36 inc. VAT£3.63 ex. VAT

-

£4.72 inc. VAT£3.93 ex. VAT

-

£4.96 inc. VAT£4.13 ex. VAT

-

£10.82 inc. VAT£9.02 ex. VAT

-

£6.74 inc. VAT£5.62 ex. VAT

-

£3.04 inc. VAT£2.53 ex. VAT