8th Feb 2023

Introducing the new Timer and Monitoring Relays!

Techna are very pleased to introduce the new extended range of Timetec Timer Relays and the brand…

Published by Darren King

Established in 1945, Techna offers an extensive range of high quality, value for money Electrical and Mechanical products. With an ever increasing portfolio of world-class products we are positioned to serve a host of markets and industries both in the UK and across the world. Complementing our own products we are also Distributors in the UK and Ireland for a wide range of world-leading electrical and mechanical component manufacturers, some of which we have represented for over 40 years.

In addition to our standard product ranges, Techna R&D provides complete electronic design and manufacture of a wide range of electronics and power control systems for our OEM customers. We cover a large spectrum of system and circuit designs including custom power controllers, sensitive/precision analogue circuits, low voltage power distribution systems, embedded devices and smart protective devices. We develop electronic systems according to customer requirements.

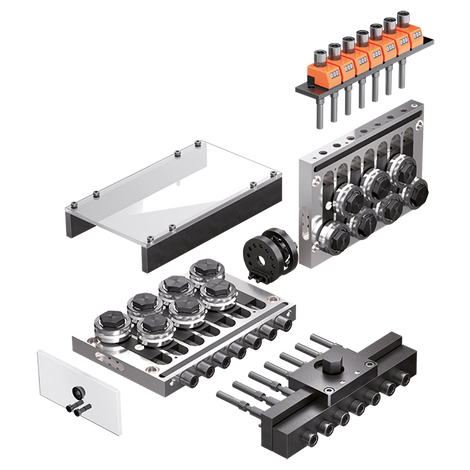

Techna are very pleased to introduce the new extended range of Timetec Timer Relays and the brand new range of Montec and Thermtec Monitoring Relays. These new Timer and Monitoring Relays are DIN rail mountable and available in a variety of different versions which have been designed to cover a wide range of applications, so suitable for most timer, voltage monitoring and temperature monitoring needs

We offer one of the world’s largest ranges of Straighteners with over 300 different variants of Roller Straightener available across 30 designs and able to handle product up to 100mm in diameter. Whatever your straightening requirements, whether Wire, Tube, Cable, Wire Rope or Strip, we have a solution.

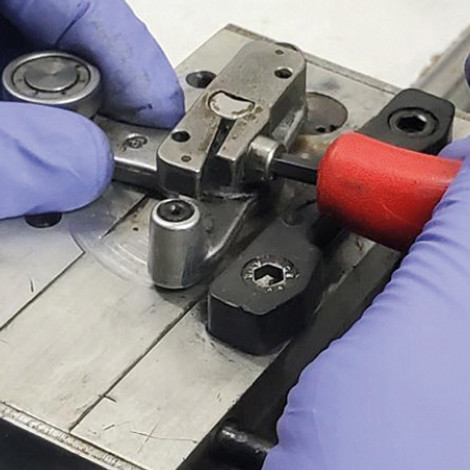

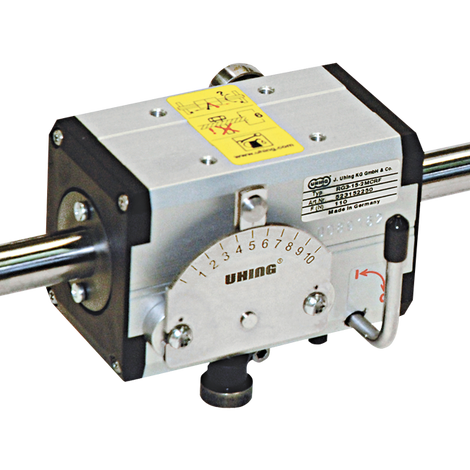

As the only fully qualified and endorsed Uhing Servicing Centre in the UK, Techna provides full servicing, setup and repair of Uhing traverse units, whatever their age and size. With Uhing trained and certified engineers we are able to refurbish drives of all sizes in our purpose built workshop.

8th Feb 2023

Techna are very pleased to introduce the new extended range of Timetec Timer Relays and the brand…

Published by Darren King

15th Dec 2022

As the only fully qualified and endorsed Uhing Servicing Centre in the UK, Techna provides ful…

Published by Darren King

25th Nov 2022

For over 40 years, Techna has worked in partnership with Witels Albert, one of the world’s lea…

Published by Darren King

24th Oct 2022

For over 40 years, Techna has worked in partnership with Joachim Uhing KG, inventors and world…

Published by Darren King